Steering Torque

Electronic Power Steering (EPS) systems are becoming prevalent in automotive systems to replace hydraulic assist power steering. The move to EPS systems is driven by the necessity for improving overall fuel efficiency, reducing system cost, improving driving experience with active cornering and adding safety features like driver drowsiness detection.

Steering torque information is always needed to drive the Steering Assist Motor. This is safety critical information – the applied torque has a direct influence on the driver’s capability to steer the vehicle.

Therefore, redundant information coming from two sensors is always needed. 1D Linear Hall sensors are used here to realize a magnetic-field amplitude measurement. Micronas solutions offer low-noise and low-offset-drift capabilities. Single- and dual-die solutions with analog or PWM output are available.

Sensor Type: 1D

Products inside:

Steering Angle

Modern Electric Power Steering (EPS) systems require the measurement of the steering position. Hall-effect sensors measuring the 360° angular information are the suitable and cost-efficient solution for a contactless steering-position measurement. The devices support state-of-the-art interfaces like PWM, SENT, and SPC. 2D Hall-effect sensors are used, because 360° angular measurement is required. Stray-field robustness is now becoming more importance due to the car electrification.

Sensor Type: 2D, TMR

Products inside:

Steering Motor - BLDC Motor

As part of the power steering system, Hall switches are used for BLDC motor commutation. To reduce the overall current consumption, the HAL 1502 3-wire version with only 1.6 mA is preferred.

TMR sensors are located at the end of shaft. They provide a very high signal resolution with stability over temperature and support up to ASIL D safety standard thanks to signal redundancy (Fail operational).

Sensor Type: Switch, TMR

Products inside:

Chassis Position Sensor

Chassis position sensors regulate the main lights for greater road safety. Depending on the load of vehicle, main headlights can blind oncoming traffic. The chassis position sensor determines the current position of the vehicle and adjusts the range of the main headlights accordingly.

The CPS is an angular sensor requiring full 360° measurement range. This measurement range is usually split into four repeating 90° or three 120° segments. The interface is usually analog, PWM, or recently also PSI5.

Sensor Type: 2D

Products inside:

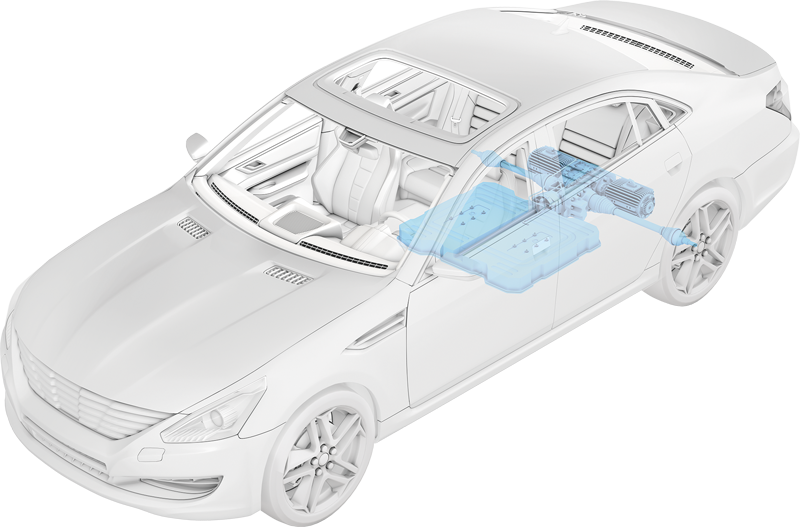

Braking Pedal

The latest generation of braking systems is taking the next step towards brake-by-wire. Those systems do not have a vacuum booster anymore. This is especially mandatory for EVs. Firstly, a position sensor is required to detect that the brake pedal is pressed to generate the hydraulic pressure. Secondly, the brake light will be activated at the car’s rear. For this, a 2D position Hall sensor can be used. If only the brake light activation is required, a 2-wire switch can be used.

Additionally, EV and HEV drive the need for stray-field robustness. Furthermore, an ISO 26262 compliant device is mandatory. Both requirements can be addressed by HAL 3930.

Sensor Type: Switch, 2D

Products inside:

Liquid Level

Hall sensors are used to detect the liquid level (e.g. brake fluid) in a tank. Linearization setpoints are required here.

Sensor Type: 1D, 3D

Products inside:

Buckle Switch

Hall switches are often used to detect whether the seat belts are used and the buckle holder is latched. Due to the greater distance from the sensor to the control unit, a 2-wire Hall switch is often the preferred sensor type for cost-saving reasons. Depending on the application setup, a unipolar or latching type can be used.

Sensor Type: Switch

Products inside:

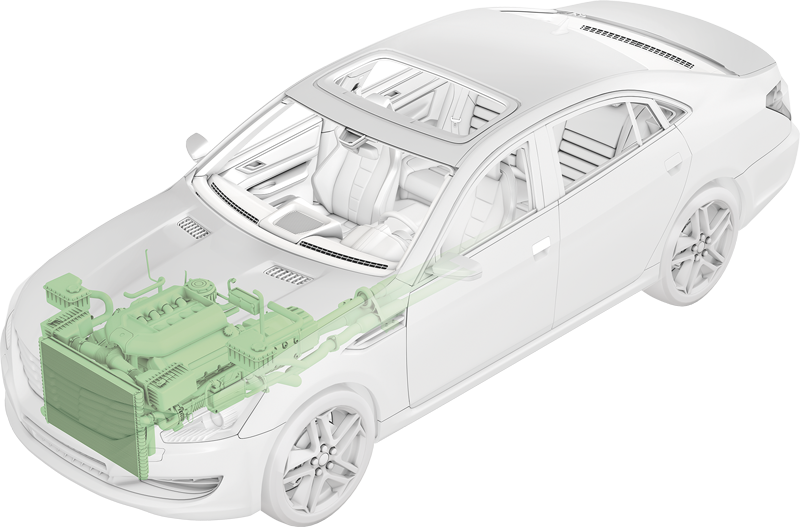

Belt Starter Generator (BSG) Motor Control

A TMR sensor measures the position of the rotor over 360°. It is located at end of shaft and provides a very high signal resolution and stability over temperature, thus reducing the angle error over lifetime.

Sensor Type: TMR

Products inside:

Brake Booster

A TMR sensor measures the position of the rotor up to 360°. It is located at end of shaft and provides a very high signal resolution and stability over temperature, thus reducing the angle error over lifetime.

Sensor Type: TMR

Products inside:

Light Detection And Ranging (LIDAR)

A TMR sensor measures the position of the spinning prism over 360° in an off-axis or end-of-shaft configuration. This angular information is used for the BLDC computation. As well, due its very high angular resolution and accuray, it is used to measure the specific angle of a laser beam reflected by an object.

The HVC drives the BLDC motor which spins the LIDAR prism.

Sensor Type: TMR

Controller Type: HVC

Products inside:

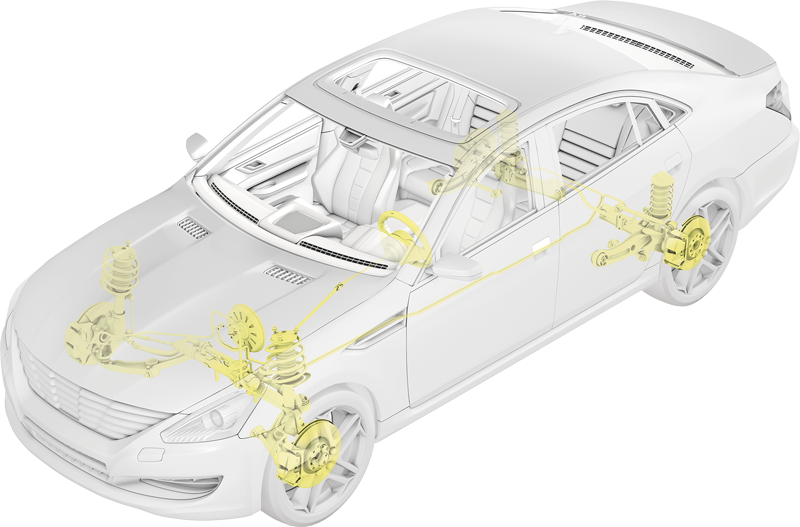

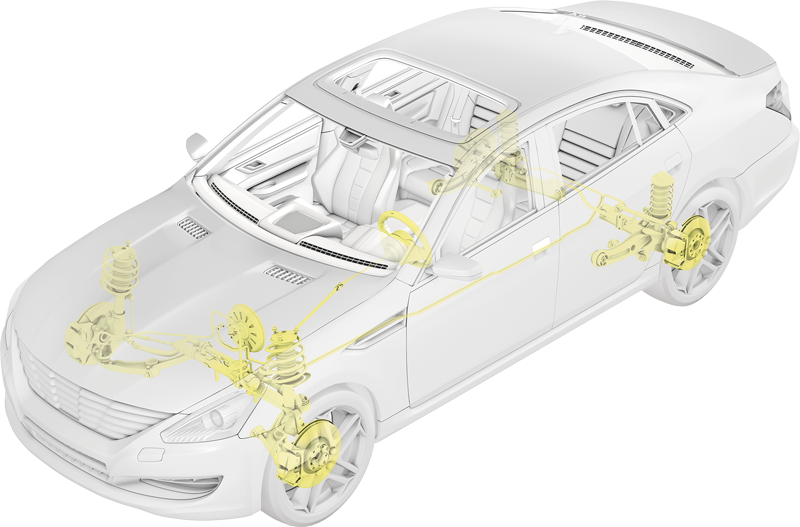

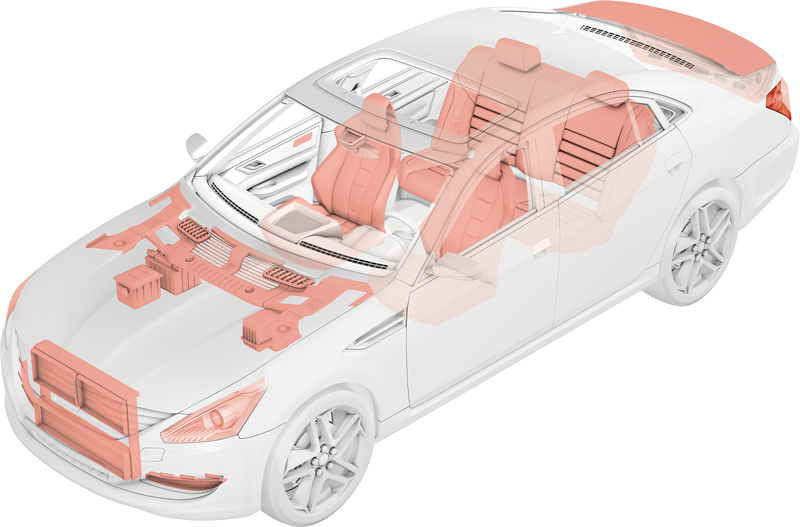

Chassis & Safety

Both comfort and safety requirements are driving the trends towards higher safety integration and safe exchange of sensor information between braking, suspension and steering modules. TDK Corporation provides highly reliable solutions for those systems and develops next-generation components addressing the needs for higher bandwidth and more functional safety. TDK offers a wide portfolio of switches, linear and angle sensors with diversified communication channels and redundancy levels.